3-PC Floating Ball Valve – Fireproof Design, Flexible Seat Seal, Full Bore - TEJI

The TEJI 3-PC Floating Ball Valve is a high-performance isolation valve engineered for reliable sealing and safety in industrial applications. Its three-piece bolted body design allows easy in-line maintenance and replacement without disturbing pipeline connections, enhancing service efficiency.

A key feature is the special seat design: at low medium pressures, the seal ring contacts the ball with a small surface area to ensure tight shutoff. As pressure increases, the elastic deformation of the seat ring enlarges the contact zone, distributing the thrust and ensuring sustained sealing without damage. This adaptive sealing ensures consistent performance under varying operating conditions.

In critical environments where fire hazards are a concern, TEJI integrates a fireproof structure. A dedicated fire-safe metal seal ring is placed behind the seat. If the PTFE or other soft seat materials degrade due to fire, the valve rapidly establishes a metal-to-metal auxiliary seal, minimizing leakage. Additionally, the middle flange sealing gasket is constructed from a spiral-wound metallic gasket to maintain integrity under high heat. This fire-safe design is fully compliant with API 607, API 6FA, and BS 6755 standards.

With high-reliability performance under pressure, temperature, and hazardous conditions, this valve is ideal for oil & gas, chemical, power generation, and other demanding services.

Specifications:

– Valve Type: 3-Piece Floating Ball Valve

– Body Design: 3-PC split-body, bolted construction

– Size Range: 2” to 24”

– Pressure Rating: ANSI Class 150 to 600

– Temperature Range: Up to 300°C (572°F)

– Bore Type: Full Bore / Reduced Bore

– End Connections: Flanged, SW (Socket Weld), BW (Butt Weld)

– Seat Design:

• Flexible, pressure-responsive seal ring

• Expanding contact area under pressure

– Fireproof Features:

• Fire-safe secondary metal-to-metal seal

• Spiral-wound metallic gasket for middle flange

• Fire Safe Compliance: API 607, API 6FA, BS 6755

– Body Materials:

• Carbon Steel: WCB, LCB

• Stainless Steel: CF8, CF8M, CF3, CF3M

• Alloy Steel: WC6, WC9, C5, C12

– Ball Materials:

• A105 + ENP

• F304, F316, F316L with coatings: Ni60, STL, TCC

– Operation Types:

• Lever

• Gear Operated

• Pneumatic

• Electric

– Standards & Compliance:

• Design Standard: API 6D

• End Flanges: ASME B16.5

• BW Ends: ASME B16.25

• Face-to-Face: ASME B16.10

• Inspection & Testing: API 598, API 6FA

• Fire Safe: API 607 / BS 6755

• Optional Compliance: NACE MR0175 / MR0103

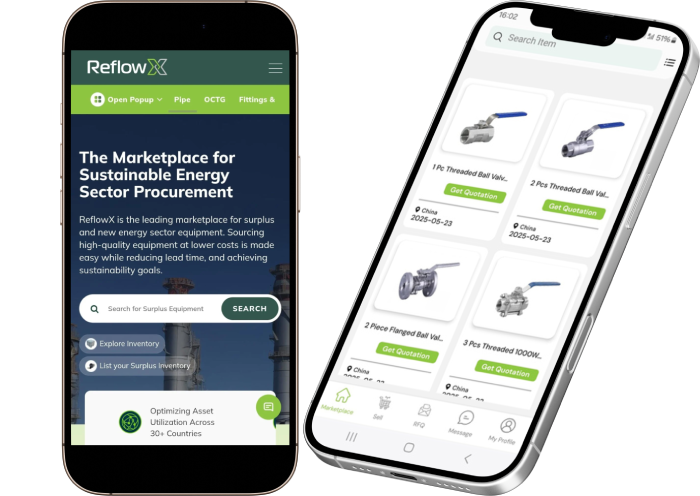

For further specifications or to inquire about this equipment and ReflowX's logistics services, Please contact ReflowX at info@reflowx.com

تسجيل الدخول باستخدام جوجل

تسجيل الدخول باستخدام جوجل

تسجيل الدخول باستخدام الفيسبوك

تسجيل الدخول باستخدام الفيسبوك

تسجيل الدخول باستخدام جوجل

تسجيل الدخول باستخدام جوجل

.jpg)

.jpg)

.jpg)

.png)

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

(1).jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.png)

(4)_1729176674.webp)