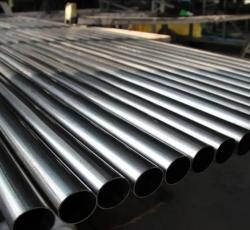

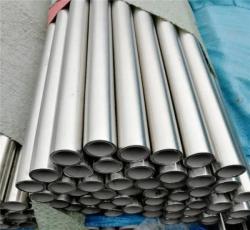

ASTM A213 Steel Pipe – Seamless Ferritic & Austenitic Alloy Steel Tubes

Handa’s ASTM A213 Steel Pipes are engineered to meet rigorous requirements in thermal and pressure-intensive systems. Manufactured as seamless ferritic and austenitic alloy steel tubes, these pipes are used extensively in boiler systems, superheaters, and heat exchangers. They offer excellent performance in high-temperature, high-pressure environments due to their alloy composition and precise thermal processing.

These pipes are produced through hot or cold finishing methods, with heat treatment options including normalizing, quenching and tempering, or stress relieving, depending on the specified grade and application. Available in a wide range of outer diameters and wall thicknesses, ASTM A213 tubes are tested and inspected under strict quality controls, including mechanical testing, hydrostatic testing, and non-destructive evaluation (eddy current or ultrasonic testing) to ensure full compliance.

Grades such as T2, T5, T9, T11, T12, T22, and T91 cater to varying performance demands, including improved creep strength, corrosion resistance, and structural integrity at elevated temperatures. These pipes are critical components in the energy, chemical, and industrial sectors where reliability and safety are paramount.

Specifications:

– Product Type: Seamless alloy steel tube

– Specification: ASTM A213

– Application: Boilers, Superheaters, Heat Exchangers

– Grades: T2, T5, T9, T11, T12, T22, T91, and others

– Material Type: Ferritic and Austenitic Alloy Steels

– Manufacturing Process:

– Hot Finished or Cold Finished

– Heat Treatment (Normalizing, Quenching & Tempering, Stress Relieving)

– Size Range: Outer diameter and wall thickness as per ASTM A213

– Temperature Resistance: Designed for high-temperature service

– Corrosion Resistance: Excellent due to alloy composition

– Mechanical Properties: Grade-dependent (yield strength, tensile strength, elongation, hardness)

– End Finishing: Plain, beveled, or as specified

– Surface Finish: As manufactured or treated

– Testing & Inspection:

– Mechanical Testing (Tensile, Hardness)

– Hydrostatic Testing

– Eddy Current or Ultrasonic Non-Destructive Testing

– Compliance: Conforms to ASTM A213 standard

– Typical Applications:

– Power Plants (Steam Generators, Heat Recovery Units)

– Chemical and Refining Industries

– Petrochemical Plants

– High-temperature Heat Transfer Systems

For further specifications or to inquire about this equipment and ReflowX's logistics services, Please contact ReflowX at info@reflowx.com

تسجيل الدخول باستخدام جوجل

تسجيل الدخول باستخدام جوجل

تسجيل الدخول باستخدام الفيسبوك

تسجيل الدخول باستخدام الفيسبوك

تسجيل الدخول باستخدام جوجل

تسجيل الدخول باستخدام جوجل

(4)_1729176674.webp)