Stainless Steel Seamless Pipe – ASTM A312/A790, Austenitic, Duplex, High-Pressure

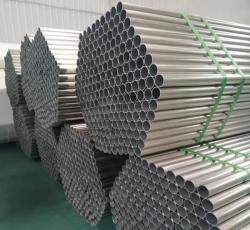

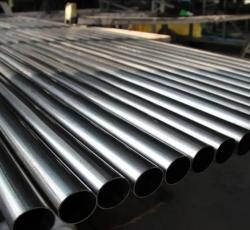

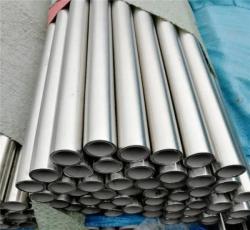

Handa’s Stainless Steel Seamless Pipes are precision-manufactured using advanced extrusion and cold drawing processes to produce hollow tubes with consistent wall thickness, superior mechanical strength, and exceptional corrosion resistance. Beginning with high-grade stainless steel billets, the material is heated and pierced to form a tube, which is then cold drawn through a series of dies to achieve the desired diameter and wall thickness.

To enhance ductility, corrosion resistance, and surface cleanliness, the pipe undergoes annealing and surface finishing procedures. Seamless pipes are particularly valued in high-pressure and high-temperature environments, as their uniform construction eliminates the risk of weld seam failures. These pipes are widely used in chemical processing, oil and gas, food and pharmaceutical industries, marine systems, structural frameworks, and thermal applications such as boilers and superheaters.

Material grades include Austenitic (304, 316, 321), Ferritic/Martensitic (410, 430), and Duplex/Super Duplex (2205, 2507), providing a wide range of mechanical and corrosion-resistant properties suited to varied industrial conditions.

Specifications:

– Product Type: Stainless Steel Seamless Pipe

– Manufacturing Method: Extrusion, Cold Drawing, Annealing, Finishing

– Size Range: As per ASTM/DIN standards (customizable)

– Wall Thickness: Uniform, based on application standards

– Standards:

– ASTM A312 (Austenitic SS)

– ASTM A790 (Duplex/Ferritic-Austenitic SS)

– DIN 17456 (Austenitic-Ferritic seamless circular tubes)

– Material Grades:

– Austenitic: 304, 316, 321

– Ferritic/Martensitic: 410, 430

– Duplex/Super Duplex: 2205, 2507

– Corrosion Resistance: Excellent (varies by grade)

– Mechanical Properties: High tensile and yield strength

– Operating Temperature: Suitable for cryogenic to high-temperature services

– Surface Finish: Bright annealed, pickled, or as required

– End Finishing: Cut, deburred, beveled or plain ends

– Applications:

– Chemical & Petrochemical

– Pharmaceutical & Food Processing

– Marine & Offshore

– Structural Components

– Heat Exchangers, Boilers, Superheaters

– Conveyance of corrosive and high-pressure fluids

For further specifications or to inquire about this equipment and ReflowX's logistics services, Please contact ReflowX at info@reflowx.com

تسجيل الدخول باستخدام جوجل

تسجيل الدخول باستخدام جوجل

تسجيل الدخول باستخدام الفيسبوك

تسجيل الدخول باستخدام الفيسبوك

تسجيل الدخول باستخدام جوجل

تسجيل الدخول باستخدام جوجل

(4)_1729176674.webp)